CAPABILITIES

Through the years MAT HD has developed expertise working closely with OE/OEM/OES to deliver solutions to each customer's unique platform. From product conception to delivery, MAT's global technical experience in the design and manufacture of complementary braking products including brake carriers, discs, drums, and hubs, as well as air disc pads, hydraulic disc pads, new and remanufactured brake shoes result in optimal product design solutions and customer satisfaction

MAT HD maintains multiple technical centers of excellence around the globe to support product development with OEM customers such as MAN Truck & Bus, Daimler, Volvo and BPW.

Dyno Testing

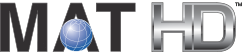

Friction

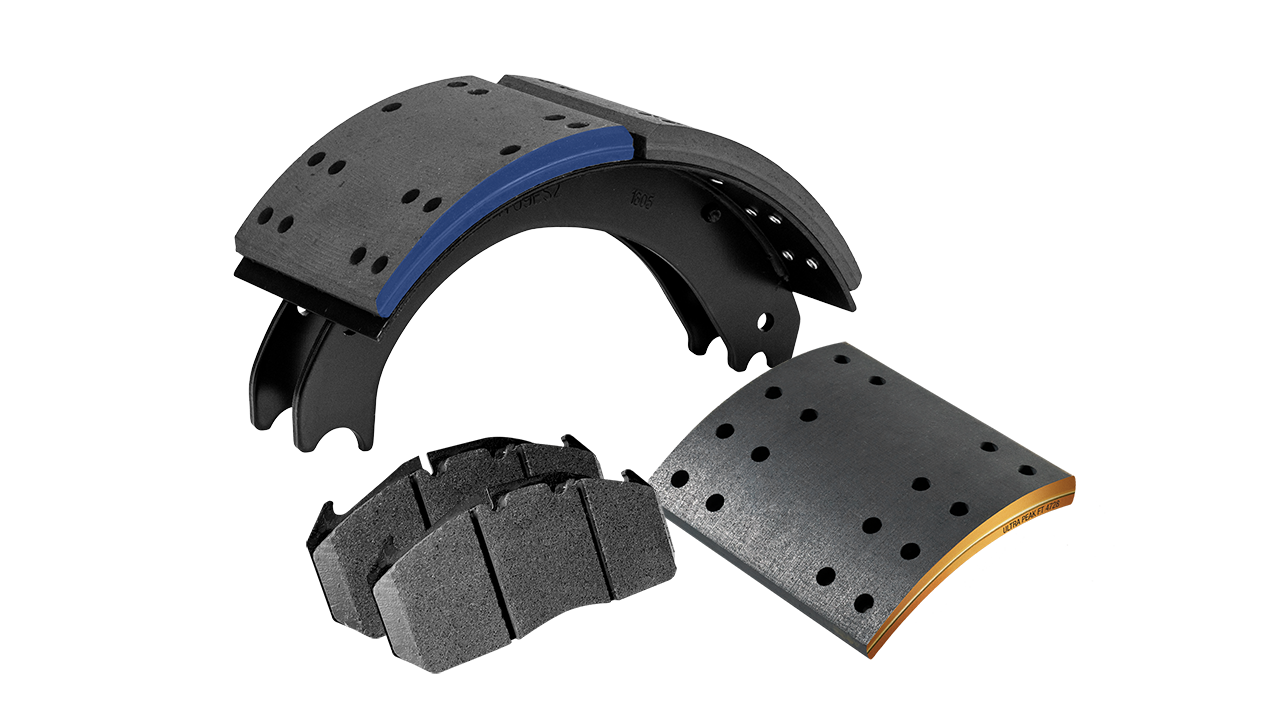

MAT Friction Group has developed a variety of OE/OEM/OES friction formulas to meet and/or exceed the quality and performance requirements for commercial and heavy duty vehicles. When developing friction formulations to satisfy ever more stringent performance and regulatory requirement in the US (FMVSS121) and European (R90), our global team of engineers relentlessly study material composition, particle size and chemistry and use in field application data to continue to extend product service life and develop cutting edge materials. All products are 100% asbestos free and all new development meets the 2025 level copper free. To stay on the forefront of material development, the Friction Group continually invests in the 36 dynos and a development team worldwide to support its' innovation and product development efforts.

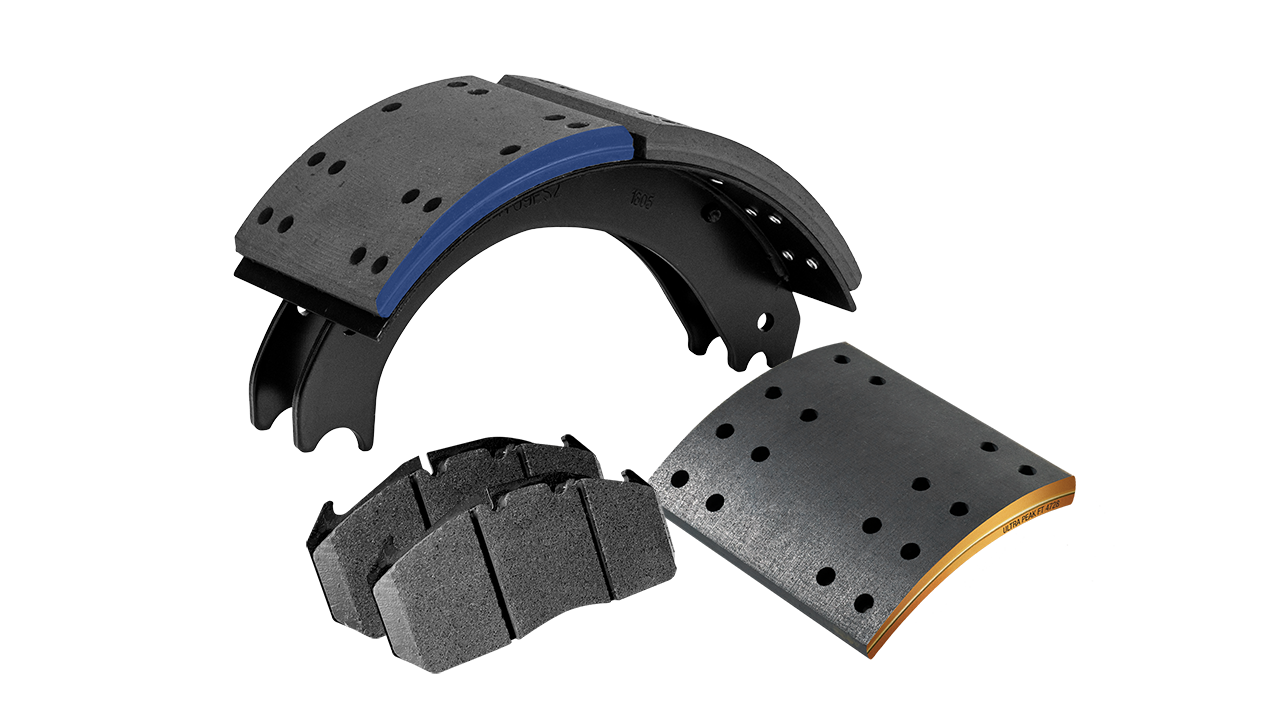

Cast Components

MAT Foundry Group specializes in the casting, machining and distribution of a variety of brake carriers, discs, drums, and hubs for commercial vehicles and trailers. MAT Foundry Group maintains 7 foundries across 3 continents with a capacity of over a half a million tons per year. MAT Foundry Group also maintains 12 machining centers to support turnkey product availability. With a highly-skilled workforce and an experienced global team of program managers and engineers, the Foundry group is able to a rapid development of new products from concepts to reality.

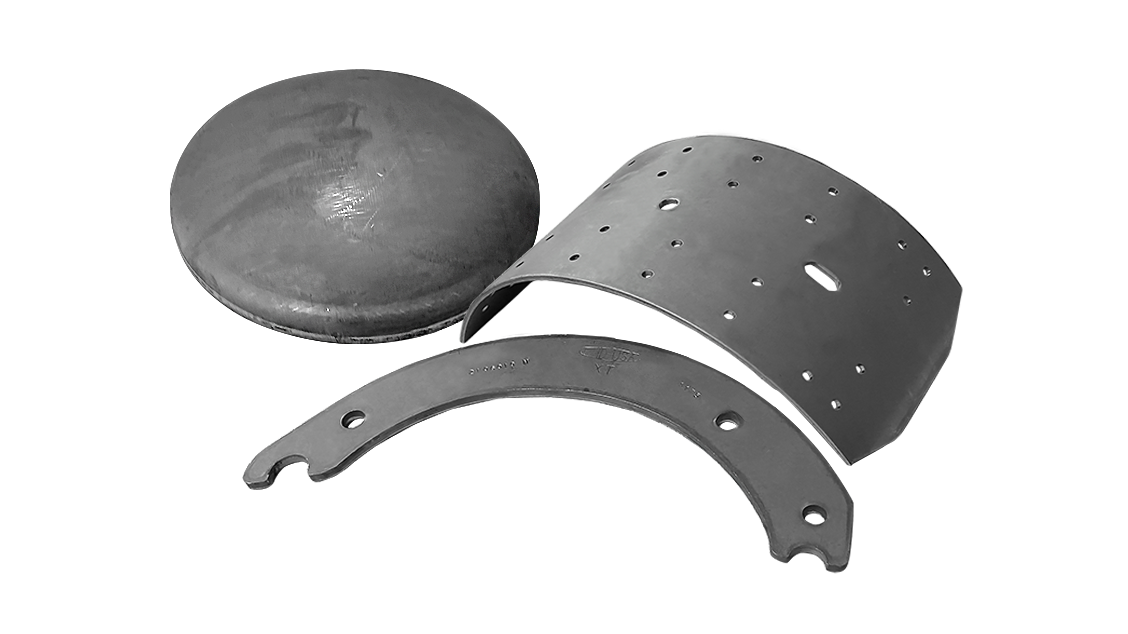

Metal Fabrication

MAT has metal fabrication sites in NA and Asia supporting new brake shoes for OE/OES/AM CV applications along with a variety of other industries ranging from transformer parts to military grade components. With an in-house tool and die shop and over 20 presses ranging from 75 tones to 1,000 tonnes, MAT HD is able to rapidly develop and deploy a wide range of stamping, welding, hardening, and coating products.

Engineered Solutions

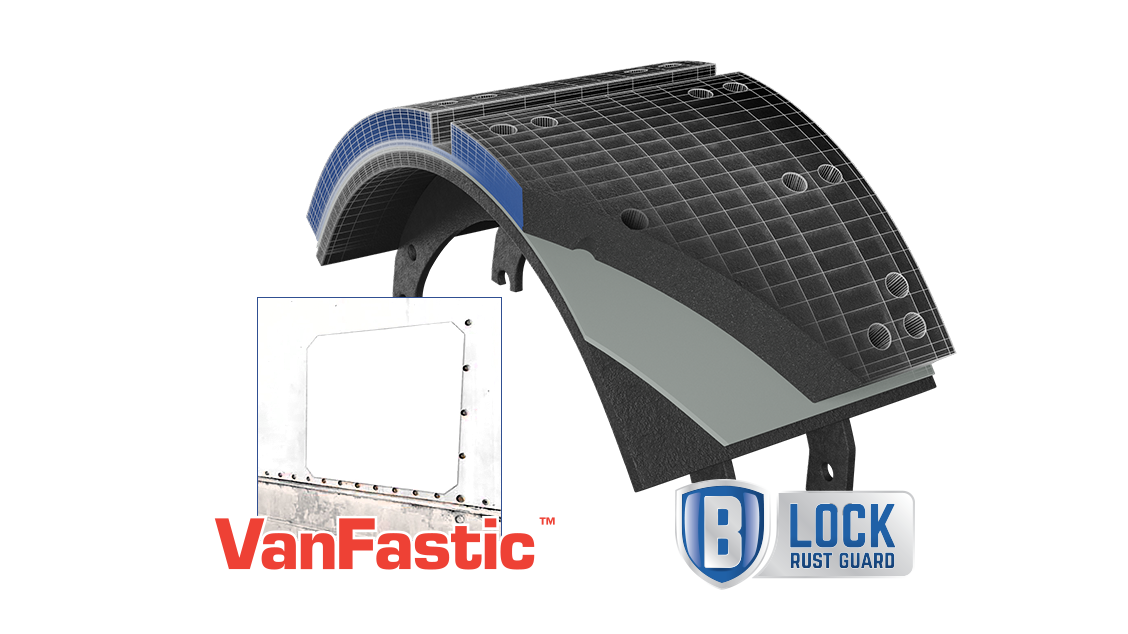

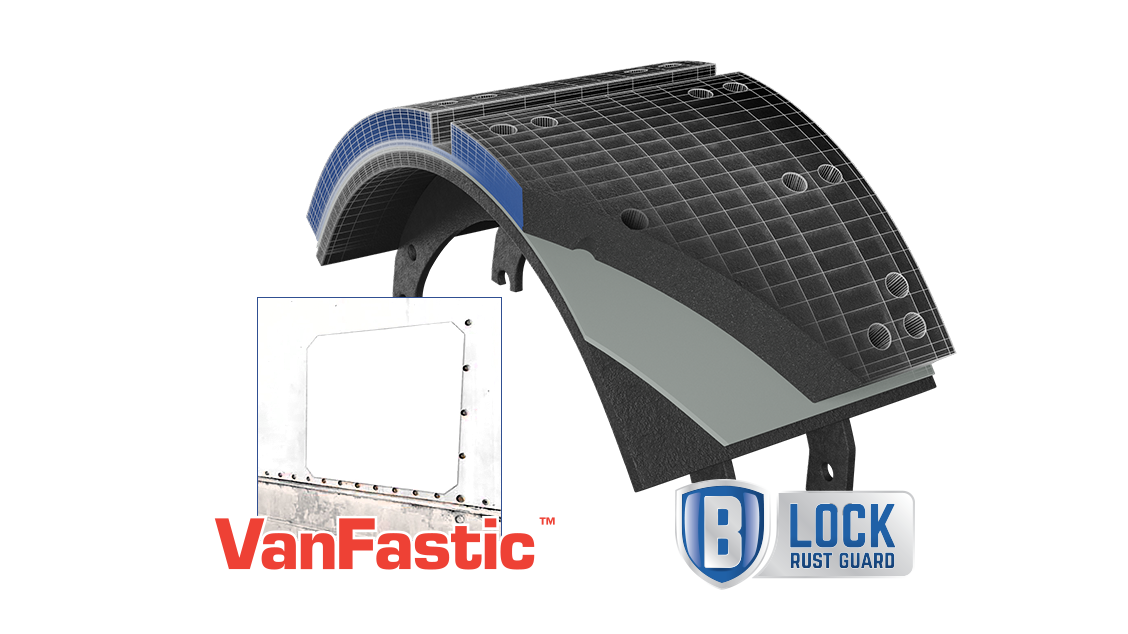

VanFastic trailer patches were designed as an easy way to quickly repair common damage to trailer bodies. By simplifying the panel repair process to an easy to use peel and stick operation, repair cost is reduced by as much as 90% while improving uptime. No fasteners are needed to install and they can be cut with scissors. Your trailer will be waterproof and airtight again.

B-Lock™ is a patented rust-prevention technology that eliminates any possibility of early deterioration of the brake shoe table and is applied to the shoe table with an adhesive before the shoe is lined. Once the lining is riveted to the B-Lock™ core, a cold bond is formed between the table of the shoe and the lining.

Friction

MAT Friction Group has developed a variety of OE/OEM/OES friction formulas to meet and/or exceed the quality and performance requirements for commercial and heavy duty vehicles. When developing friction formulations to satisfy ever more stringent performance and regulatory requirement in the US (FMVSS121) and European (R90), our global team of engineers relentlessly study material composition, particle size and chemistry and use in field application data to continue to extend product service life and develop cutting edge materials. All products are 100% asbestos free and all new development meets the XXX level copper free. To stay on the forefront of material development, the Friction Group continually invests in the 36 dynos and a development team worldwide to support its' innovation and product development efforts.

Components

MAT Foundry Group specializes in the casting, machining and distribution of a variety of brake carriers, discs, drums, and hubs for commercial vehicles and trailers. MAT Foundry Group maintains 7 foundries across 3 continents with a capacity of over a half a million tons per year. MAT Foundry Group also maintains 12 machining centers to support turnkey product availability. With a highly-skilled workforce and an experienced global team of program managers and engineers, the Foundry group is able to a rapid development of new products from concepts to reality.

Metal Fabrication

MAT has metal fabrication sites in NA and Asia supporting new brake shoes for OE/OES/AM CV applications along with a variety of other industries ranging from transformer parts to military grade components. With an in-house tool and die shop and over 20 presses ranging from 75 tones to 1,000 tonnes, MAT HD is able to rapidly develop and deploy a wide range of stamping, welding, hardening, and coating products.

Engineered Solutions

VanFastic trailer patches were designed as an easy way to quickly repair common damage to trailer bodies. By simplifying the panel repair process to an easy to use peel and stick operation, repair cost is reduced by as much as 90% while improving uptime. No fasteners are needed to install and they can be cut with scissors. Your trailer will be waterproof and airtight again.

B-Lock™ is a patented rust-preventative technology that eliminates any possibility of early deterioration of the brake shoe table and is applied to the brake shoe table in an adhesive tape from before the shoe is lined. Once the lining is riveted to the B-Lock™ core, a cold bond is formed between the table of the shoe and the lining.